What I find really striking about the difference between the Singer Heavy Duty- a contemporary plastic fantastic sewing machine by Singer and the older models is this- one machine assumes you actually know what your doing and the other assumes that sewing is a merely hobbyistic pursuit. The stronger, well built sewing machines actually acknowledge sewing as a technical skill. The Singer 401G is a machine built to punch through anything from making clothes to curtains. It was also known charmingly as the slant-o-matic and was engineered to be the best of its day. I found my slant-o-matic during the pandemic in Ireland, when filming on The Last Duel was postponed.

Last August when I returned from spending the summer in Malta on Gladiator 2, my little brown hen- Singer 401G, she broke down. Lacking the personal bandwidth to deal with problem after a busy shoot, I took little brown hen to the local sewing machine shop. Where unfortunately, the mechanic did not quite know what to do with a Machine that was built in 1952 and was not made for planned obsolescence. So after waiting the guts of six months to report he had fixed my sewing machine, I game him an ultimatum and when he produced no results, I rescued Hen from his shop.

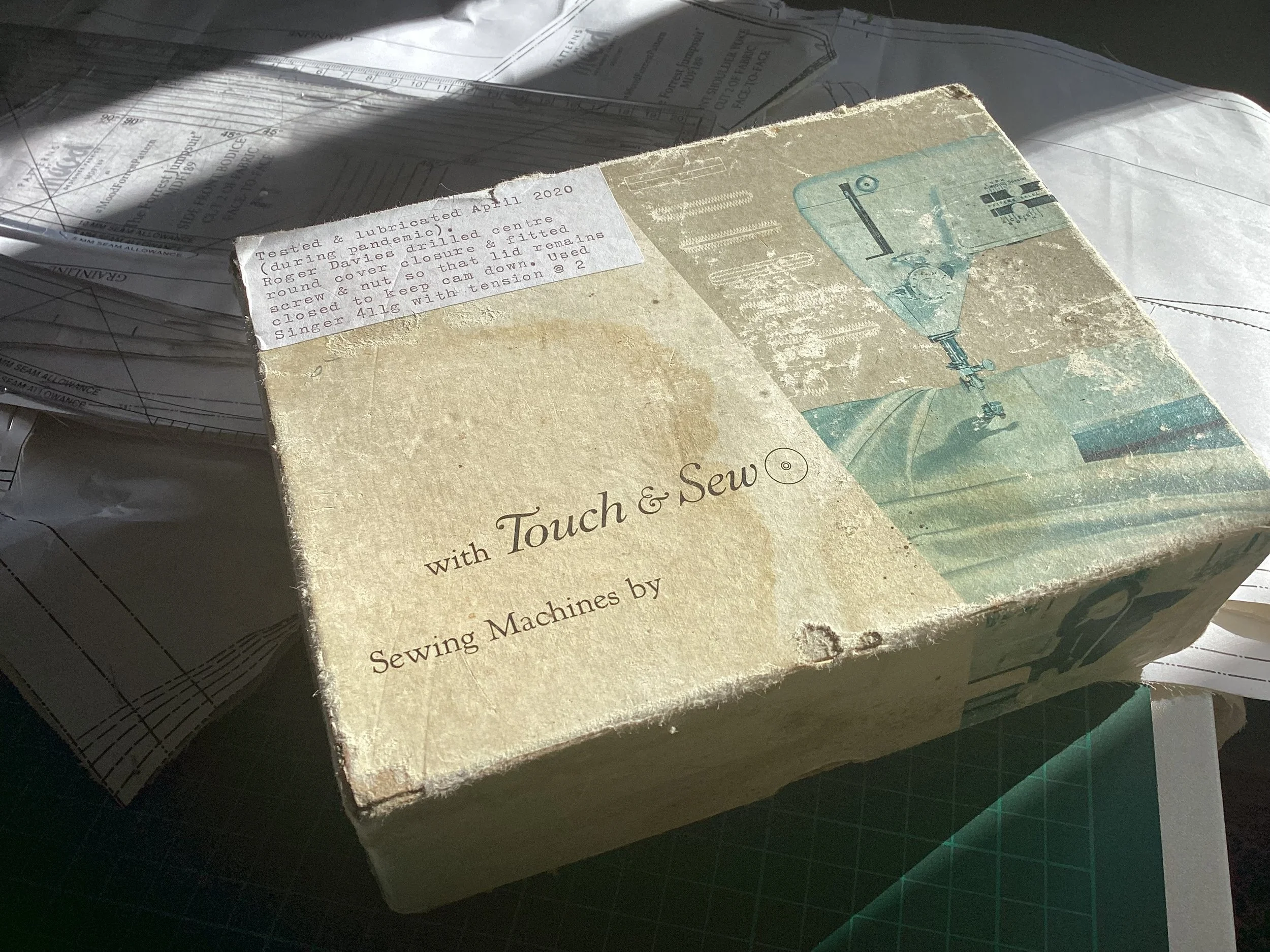

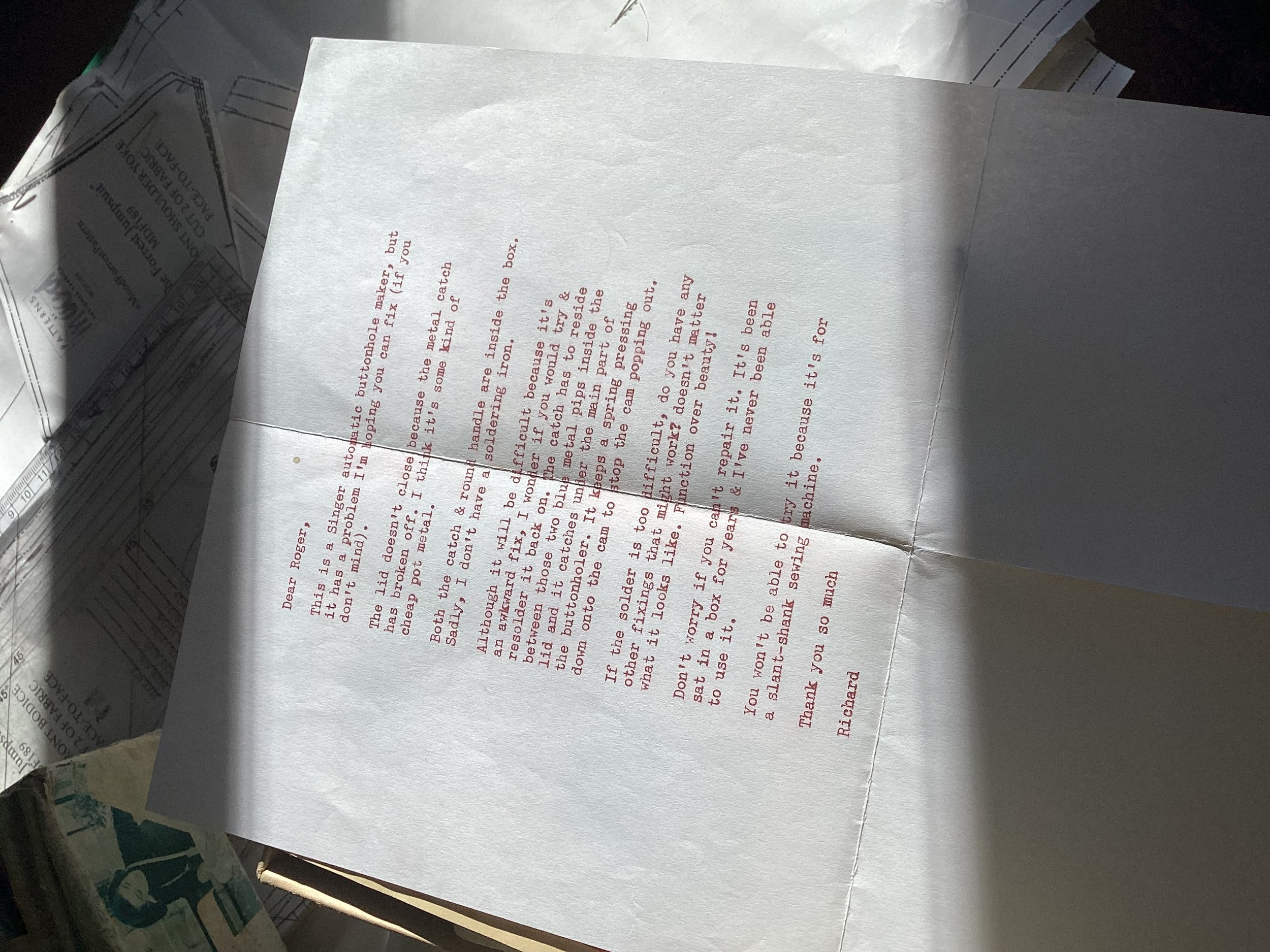

What had caused the problem was that the stitch selector arms had moved and needed to be reset and timed. Also the needle driving shaft was pushed to far forward. I was testing a new buttonholing attachment that was made for the machine in the late 1950s and early 1960s when I realised there was something seriously wrong with the control centre of the machine. Why the interest in buttonholing attachments you might ask? Currently the only place to get keyhole buttonholes regularly in London is a back alley in Soho. Bit of a trek. Being able to do buttonholes in house is more efficient and less stress. Ironically, this buttonhole attachment was in turn someone else’s pandemic passion project. As can be seen by the note inclosed in the box, which appears to have been done on a typewriter.

In short, I found the manual posted online by another sewing machine enthusiast and proceeded to service the machine top down myself. In order to fix the control centre I had to get some very stuck screws out without buggering them. I took the machine to B&Q and found the correct size screwdriver. I then used a crème brûlée torch from my kitchen to apply some heat to loosen the screws and 3 hours later, Hey Presto! I have my favourite sewing machine back in working order. I Also changed out the original lamp which is too yellow and rather like a candle to a high watt LED. Much better.

Defo going to use the crème brûlée torch this week for some actual baking and not as an improvised blow torch.

Needless to say, my 85 year old mechanical engineer of a Grandad was very proud of me!